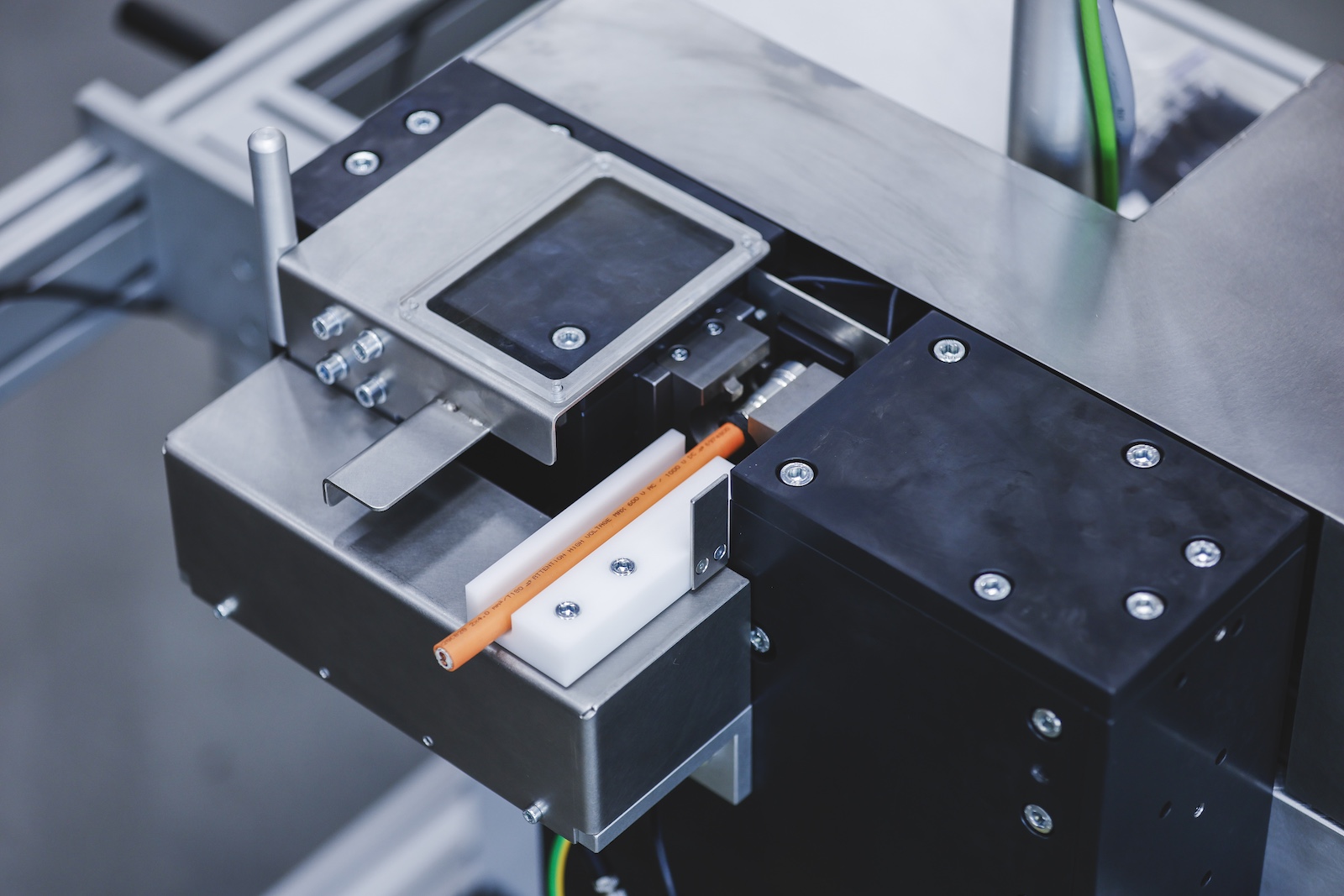

Ensure quality, efficiency, and flexibility in your high-voltage cable assembly processes. With WKM, you get machinery solutions tailored to your needs – from standard to specialized setups. Whether you’re working with various connector types or aiming for cost-effective production, our scalable systems adapt to your volume and project phase. We support you in all key process steps of Shield Sleeve Crimping, Contact Carrier Assembly, Seal Mounting, End Cap Closing, and more…

Streamline your processes and secure reliable, repeatable results with WKM.

Modular toolsets to process different connectors

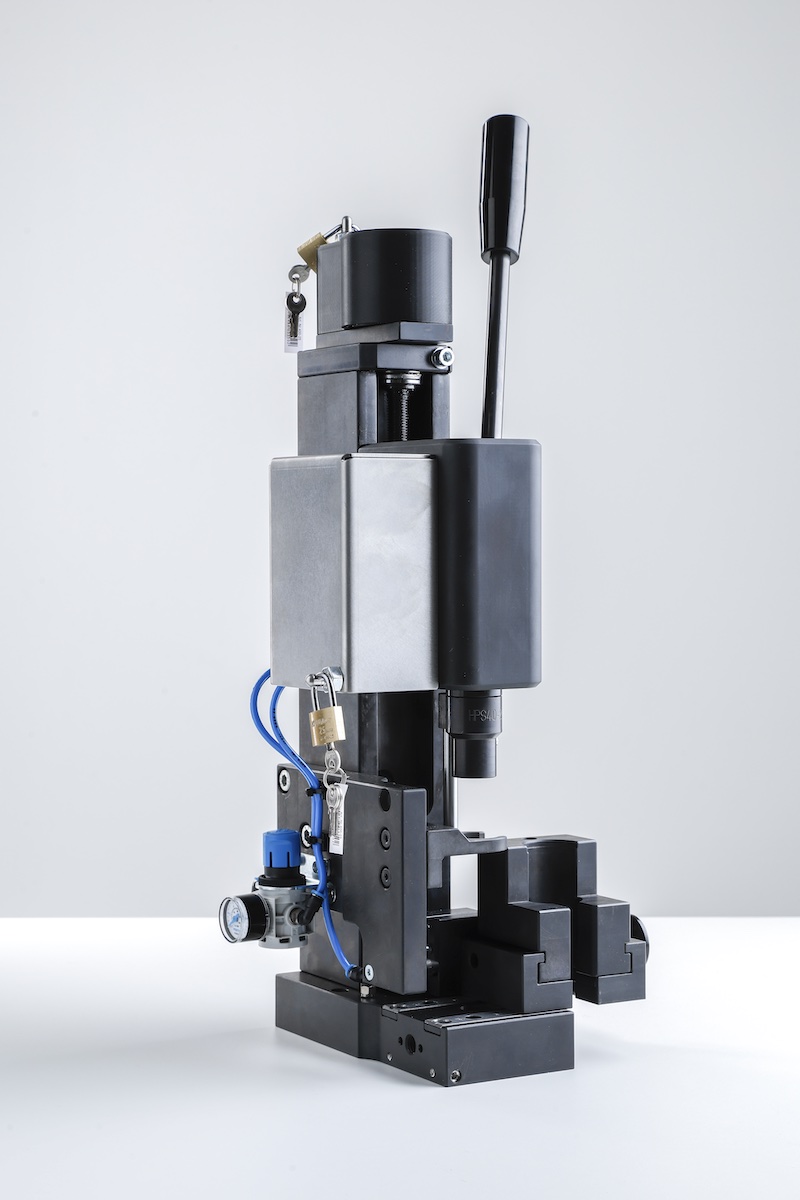

Manual and mobile solution for low volume and service application

Easy change of crimping tools

Cost efficient solution

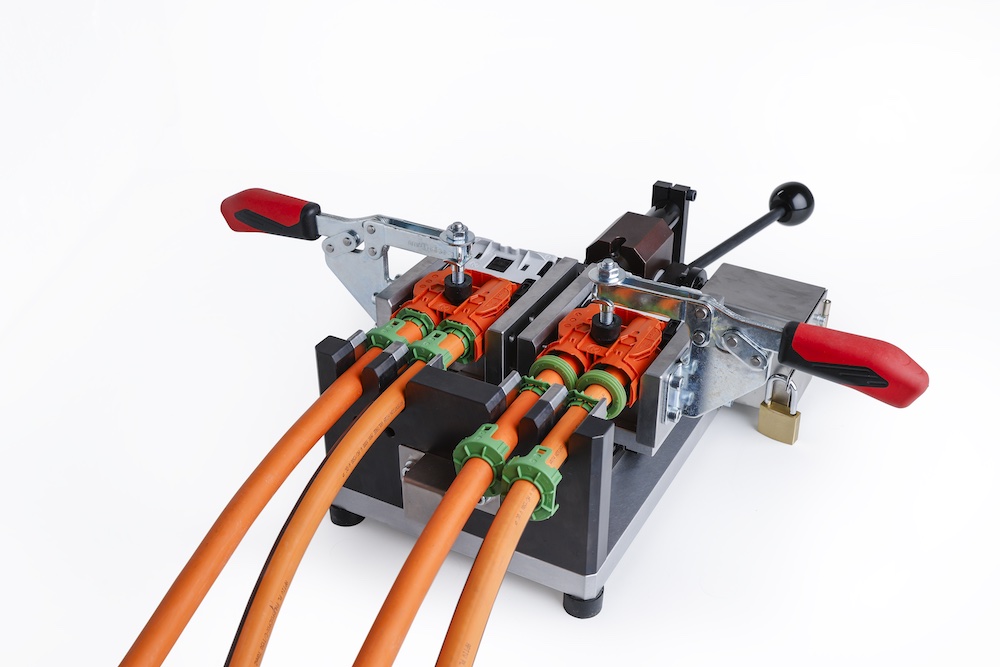

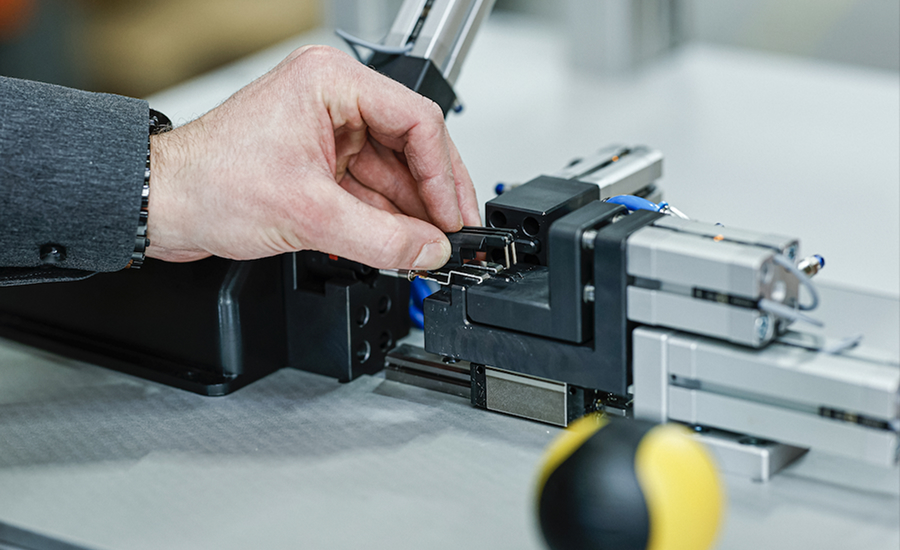

Contact carrier assembly of all HPS40 Hirschmann connectors. The machines are designed for easy, accurate and reliable assembly of connector parts.

Assembly steps of various other manufacturers are possible.

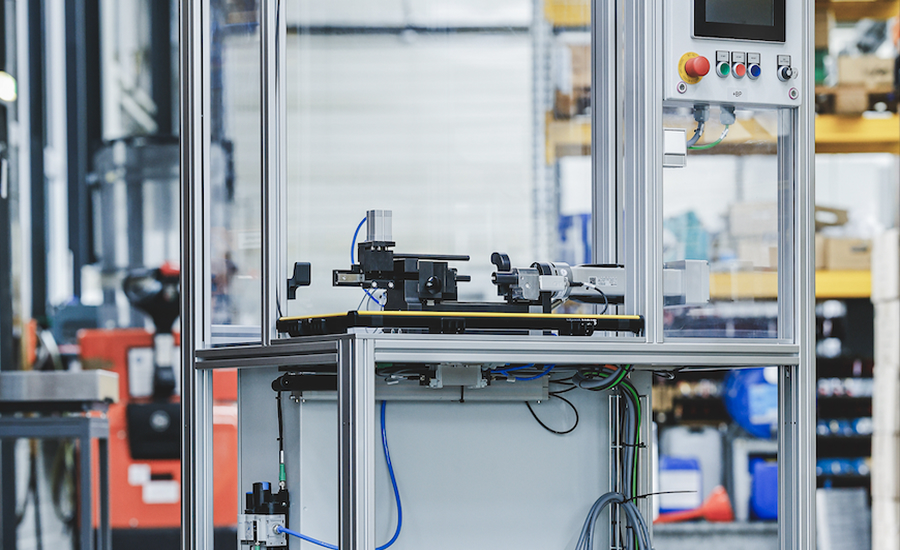

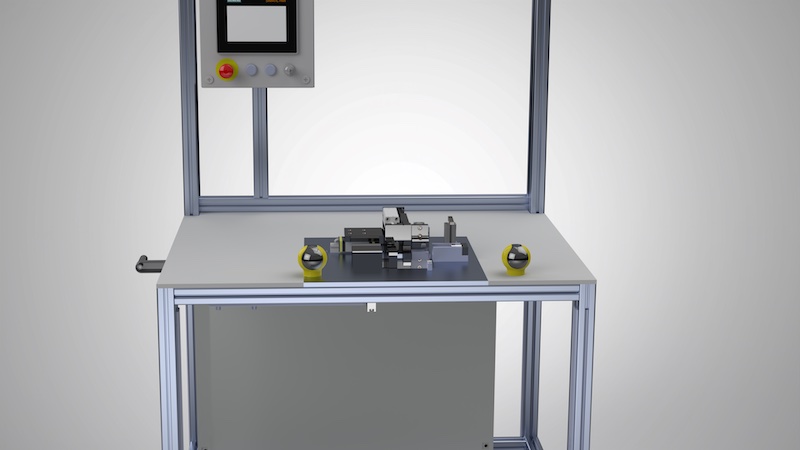

Our Final Assembly Solutions (FAS) enable precise, efficient and process secure assembly of a wide range of connectors.

Easy change of tool sets: Vertical and horizontal operation possible

Return stroke lock

Contact carrier into contact housing

Contact carrier into shield sleeve

Overhousing on connector

Other connector types on request!

Solutions for processing of seals and cover/endcap closing from manual to semi automatic machines.

Various connectors and changeable tools to support productions in efficiency (Hirschmann, Kostal, Aptiv, TE Connectivity, …).

Force control possible

Development of customer specific systems for reliable, process-secure production or measurement requirements.

We offer standard solutions for the following connector manufacturers, and our portfolio for connectors and processes is continuously expanding.

With us, you’re not just buying equipment – you’re gaining a committed partner focused on your success.

Mastering high precision machining and IT system integration according to your needs (including OPC UA)

In-house measuring equipment to ensure accuracy prior delivery

Solutions

sold

Global cable assembly customers

Countries supplied

Contact us and we will take the time to discuss your challenges.

Together we will find the right solutions.